Transducers Basics and Their Applications in Aerospace

Global electronic component supplier ERSAELECTRONICS: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

What is A Transducer?

Transducers are electronic devices that convert one form of energy into another. It serves as a bridge between the physical world and the electrical domain, enabling the measurement and processing of various physical quantities. Transducers are widely used in numerous fields, including engineering, medicine, telecommunications, and many others.

One of the primary functions of a transducer is to convert a physical quantity, such as temperature, pressure, or sound, into an electrical signal that can be easily measured or processed. This conversion process involves the transduction principle, where the transducer transforms the input energy into a corresponding output signal. The output signal can be in the form of voltage, current, frequency, or any other electrical parameter that represents the physical quantity being measured.

Transducers come in various types and designs, each tailored to specific applications and requirements. Some common types of transducers include sensors, actuators, microphones, speakers, and ultrasound devices. Sensors, for example, are transducers that detect and measure physical phenomena such as light, temperature, pressure, or motion. They convert these physical quantities into electrical signals that can be further analyzed or utilized in control systems.

Microphones and speakers are transducers used in audio applications. Microphones convert sound waves into electrical signals, while speakers convert electrical signals into sound waves. These transducers enable the recording and reproduction of sound, making them essential components in communication systems, entertainment devices, and public address systems.

Ultrasound transducers are another important type used in medical imaging. They emit high-frequency sound waves into the body and receive the echoes produced by the internal structures. These echoes are then converted into electrical signals, which are processed to create detailed images of the body's organs and tissues. Ultrasound transducers have revolutionized medical diagnostics, allowing non-invasive imaging and aiding in the diagnosis of various conditions.

In summary, transducers are versatile devices that convert one form of energy into another, typically from a physical quantity to an electrical signal. They are essential in a wide range of applications, enabling the measurement, control, and processing of various physical phenomena. With their diverse types and designs, transducers continue to advance technology and contribute to numerous fields, making them indispensable components in modern society.

How do Transducers Work?

Transducers work based on the principle of transduction, which involves the conversion of one form of energy into another. The specific mechanism of operation depends on the type of transducer and the physical quantity being measured or converted.

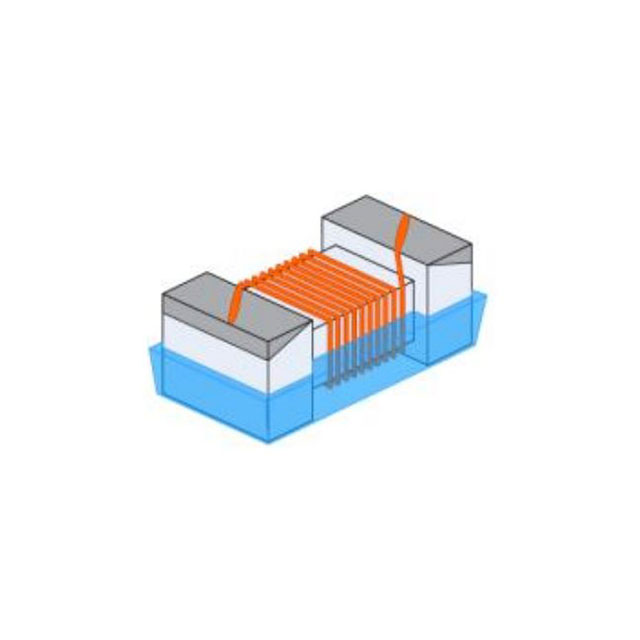

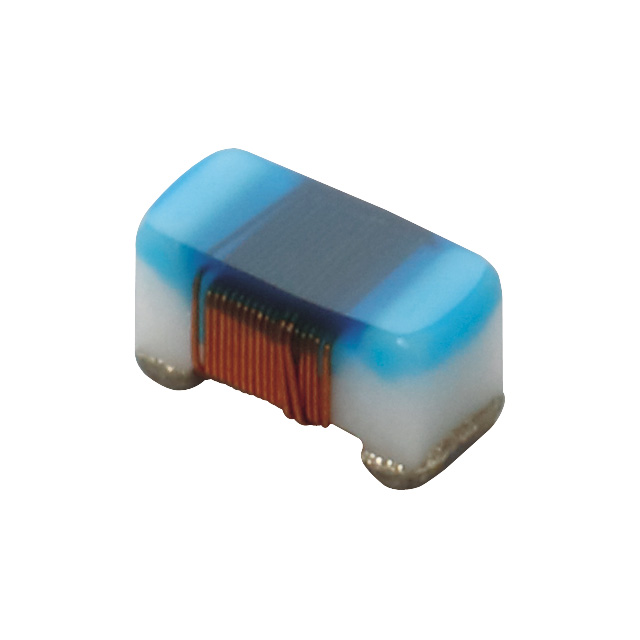

In general, transducers consist of two main components: a sensing element and a signal conditioning circuit. The sensing element is responsible for detecting the physical quantity and converting it into a measurable electrical signal. The signal conditioning circuit processes and amplifies the electrical signal to make it suitable for further analysis or utilization.

The sensing element of a transducer can employ various principles to convert the input energy into an electrical signal. For example, in a temperature transducer, a thermocouple or a resistance temperature detector (RTD) can be used. A thermocouple generates a voltage proportional to the temperature difference between its two junctions, while an RTD changes its resistance with temperature. Both of these sensing elements convert the temperature into an electrical signal that can be measured.

Similarly, in a pressure transducer, a common sensing element is a strain gauge. A strain gauge consists of a thin wire or foil that deforms under the influence of pressure, causing a change in its electrical resistance. This change in resistance is then converted into an electrical signal, which represents the pressure being measured.

In the case of a microphone, the sensing element is typically a diaphragm that vibrates in response to sound waves. These vibrations are then converted into electrical signals through various mechanisms, such as electromagnetic induction or piezoelectric effect. The electrical signals can then be amplified and processed to reproduce the sound.

Once the sensing element converts the physical quantity into an electrical signal, the signal conditioning circuit comes into play. This circuitry is responsible for amplifying, filtering, and shaping the electrical signal to make it suitable for further processing or measurement. It may involve components such as amplifiers, filters, analog-to-digital converters, and digital signal processors.

The output of the transducer, after signal conditioning, can be in various forms depending on the application. It can be a voltage, current, frequency, or any other electrical parameter that represents the physical quantity being measured. This output can then be used for monitoring, control, analysis, or transmission purposes.

In summary, transducers work by converting one form of energy, such as temperature, pressure, or sound, into an electrical signal. The sensing element detects the physical quantity and converts it into an electrical signal, while the signal conditioning circuit processes and amplifies the signal. This enables the measurement, control, and utilization of various physical phenomena in a wide range of applications.

The most common transducer is a pressure transducer. Here I present a related video about how it works:

Transducers vs Transmitters

Transducers and transmitters are both devices used in the field of instrumentation and measurement, but they serve different purposes and have distinct functionalities.

A transducer, as mentioned earlier, is a device that converts one form of energy into another. It can be used to measure physical quantities such as temperature, pressure, or sound and convert them into electrical signals. Transducers are typically passive devices that do not require an external power source to operate. They act as sensors, detecting and converting the physical quantity into an electrical signal that can be further processed or measured. Transducers are commonly used in applications such as sensors, microphones, speakers, and ultrasound devices.

On the other hand, a transmitter is a device that generates and sends out signals or information. It is an active device that requires an external power source to operate. Transmitters are commonly used in communication systems to transmit signals over long distances. They take an electrical signal as input and convert it into a form suitable for transmission, such as radio waves or optical signals. Transmitters are often used in applications such as radio broadcasting, wireless communication, and satellite communication.

While both transducers and transmitters involve the conversion of energy, their primary functions and applications differ. Transducers focus on the measurement and conversion of physical quantities into electrical signals, while transmitters focus on generating and transmitting signals over long distances.

It is worth noting that there can be instances where a device can function as both a transducer and a transmitter. For example, in the case of a microphone, it acts as a transducer by converting sound waves into electrical signals. However, if the microphone is connected to a wireless system that transmits the electrical signals to a receiver, it also functions as a transmitter.

Transducers in Aerospace Applications

Transducers play a vital role in aerospace applications, where accurate and reliable measurements are crucial for the safe and efficient operation of aircraft and spacecraft. They are used in various systems and components to monitor and control different parameters. Here are some key areas where transducers are commonly employed in aerospace:

1. Pressure Measurement: Transducers are extensively used to measure pressure in aerospace applications. They are employed in aircraft engines to monitor combustion chamber pressure, turbine inlet pressure, and compressor discharge pressure. In spacecraft, transducers are used to measure propellant tank pressure, engine chamber pressure, and atmospheric pressure during re-entry.

2. Temperature Measurement: Transducers are employed to measure temperature in aerospace systems. They are used to monitor engine exhaust gas temperature, oil temperature, coolant temperature, and cabin temperature. Temperature transducers are crucial for ensuring optimal performance, preventing overheating, and maintaining safe operating conditions.

3. Acceleration and Vibration Measurement: Aerospace vehicles experience various forces and vibrations during operation. Transducers, such as accelerometers, are used to measure acceleration and vibrations in aircraft and spacecraft. This data is essential for structural health monitoring, flight control systems, and ensuring the safety and stability of the vehicle.

4. Load and Force Measurement: Transducers are used to measure loads and forces in aerospace structures and components. They are employed in aircraft wings, landing gear, and engine mounts to monitor structural loads and ensure they remain within safe limits. Force transducers are also used in rocket engines to measure thrust and optimize performance.

5. Level and Flow Measurement: Transducers are used to measure fluid levels and flow rates in aerospace systems. They are employed in fuel tanks to monitor fuel levels, ensuring accurate fuel management and preventing fuel starvation. Flow transducers are used in hydraulic and pneumatic systems to measure fluid flow rates and ensure proper system operation.

6. Position and Displacement Measurement: Transducers, such as linear and rotary encoders, are used to measure position and displacement in aerospace applications. They are employed in control surfaces, landing gear, and engine components to monitor their positions and ensure precise control and operation.

Transducers used in aerospace applications must meet stringent requirements for accuracy, reliability, durability, and resistance to harsh environmental conditions. They undergo rigorous testing and certification processes to ensure their performance and compliance with aerospace standards.

Conclusion

In summary, transducers are extensively used in aerospace applications for measuring and monitoring various parameters such as pressure, temperature, acceleration, load, flow, and position. They play a critical role in ensuring the safe and efficient operation of aircraft and spacecraft, contributing to the overall performance, control, and reliability of aerospace systems.

.png?x-oss-process=image/format,webp/resize,h_32)